Výstavba betonových konstrukcí pomocí 3D tisku (aditivní robotické fabrikace) patří nepochybně k nadějným stavebním technologiím budoucnosti. Pokud je navíc pro tisk použita směs ultra vysokohodnotného betonu (UHPC) s dostatečnou dávkou ocelových mikrovláken, otevírá se potenciál výroby velmi subtilních nosných konstrukcí s vysokou duktilitou. V návaznosti na výsledky výzkumu základních mechanických vlastností 3D tištěného UHPC, které byly prezentovány autory v předchozím roce, představuje tento článek výsledky nové série experimentů, zaměřené na odezvu tenkých těles v ohybu. Zvláštní pozornost je věnována parametrům, u kterých lze obecně předpokládat jejich možný vliv na výslednou ohybovou pevnost.

V časopisu Beton 3/2022 autoři článku prezentovali prvotní výsledky dosažené technologií 3D tisku UHPC s ocelovými mikrovlákny [15]. Bylo ukázáno, že při optimalizaci složení směsi a typu vláken, směru tisku a způsobu ošetřování je možné dosáhnout stejných, nebo dokonce lepších mechanických vlastností než při konvenční výrobě UHPC – pevnosti v tlaku až 160 MPa, pevnosti v ohybu více než 25 MPa a modulu pružnosti blížícímu se k 55 GPa, a to při dávkování drátků 120 kg/m3. V návaznosti na dosažené poznatky byla další fáze výzkumu zaměřena na ohybovou pevnost tenkých těles.

Terminologie

V textu je používáno několik výrazů a zkratek, které nejsou z čistě formálního hlediska terminologicky zcela správné. Výraz beton je používán i pro cementový kompozit, který neobsahuje hrubé kamenivo (tj. správně malta). Zkratka UHPC označuje ultra vysokohodnotný beton, i pokud obsahuje vlákna (někdy označováno jako UHPFRC). Jako 3D tisk je označena technologie výroby konstrukčních prvků pomocí extruze a postupného vrstvení hmoty, ačkoliv přesnějším označením je aditivní robotická fabrikace. A nakonec ohybovou pevností je myšlena pevnost stanovená při ohybové zkoušce (běžně používaným výrazem je pevnost v tahu za ohybu).

Úvod a stručná teorie

Ve spolupráci společností So Concrete a Valbek a Katedry betonových a zděných konstrukcí FSv ČVUT v Praze byly zkoumány možnosti využití UHPC pro konstrukční prvky staveb. S ohledem na vysoké hodnoty jeho mechanických vlastností a s ohledem na vysokou cenu v porovnání s běžným betonem má ultra vysokohodnotný beton největší potenciál při realizaci velmi subtilních (tenkostěnných) konstrukčních prvků. Tato skutečnost je umocněna při využití technologie 3D tisku, díky níž je možné vytvářet prvky téměř libovolných tvarů bez technických omezení souvisejících s běžnou betonáží do bednění.

Z uvedených důvodů byla druhá fáze výzkumu zaměřena na pevnost v ohybu a celkovou odezvu tenkých konstrukčních prvků s důrazem na zkoumání parametrů, které mohou ovlivnit nominální ohybovou pevnost a které jsou popsány dále.

Vliv velikosti tělesa

Vliv velikosti tělesa (anglicky size effect) je dnes již poměrně dobře pochopeným jevem. Ve stručnosti lze uvést, že důsledkem size effectu mají menší tělesa tendenci vykazovat vyšší nominální hodnoty pevnosti než tělesa větších rozměrů. Obecně se rozlišuje několik typů, z nichž dva nejdůležitější jsou:

- statistický size effect,

- deterministický (energetický) size effect.

Statistický size effect se projevuje u většiny materiálů a nejjednodušší analogií k jeho popisu je představa řetězu. Lze předpokládat, že pevnost každého článku řetězu je vlivem drobných vad ve struktuře materiálu rozdílná, přičemž tento rozdíl v pevnosti každého článku lze popsat statistickým rozdělením (nejpoužívanějším je Weibullovo rozdělení pravděpodobnosti [16]). Čím delší bude řetěz, resp. čím více článků bude obsahovat, tím vyšší je pravděpodobnost, že jeden z článků bude vykazovat velmi nízkou pevnost, a proto i celý řetěz jako celek vykáže velmi nízkou únosnost. Obdobně lze u větších betonových prvků očekávat vyšší pravděpodobnost existence výrazné vady (např. dutiny, mikrotrhliny apod.), ze které bude iniciováno šíření poškození do zbytku tělesa.

Naopak deterministický size effect se projevuje pouze u kvazikřehkých materiálů (jako je beton, horniny, keramika apod.). Důležitou vlastností těchto materiálů je tzv. charakteristický rozměr, tj. materiálová konstanta, která je nezávislá na velikosti tělesa. Za charakteristický rozměr lze u betonových konstrukcí považovat velikost nelineární (plastické) procesní zóny dle teorie lineární lomové mechaniky nebo lze analogicky uvažovat velikost pásu poškození (tzv. crack band v případě tahu, resp. crush band v případě tlaku). Zatímco míra spotřebované energie na šíření trhliny je lineárně úměrná velikosti prvku, tak míra uvolněné energie je převážně kvadraticky úměrná velikosti prvku, a tento nesoulad vede nakonec opět na vyšší nominální hodnoty pevnosti u malých těles a k poklesu pevnosti u těles velkých.

Podrobnosti včetně popisu dalších typů size effectu přesahují záměr tohoto článku a lze je nalézt např. v rozsáhlých monografiích a článcích prof. Bažanta [2], [3], [4], [5] ad.

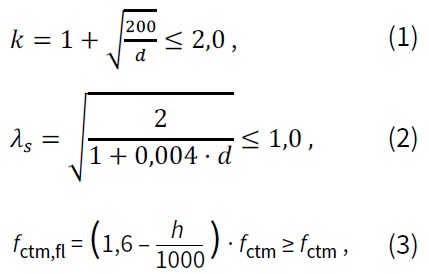

Je vhodné zmínit, že vliv skutečné velikosti nosných prvků je v současných normových postupech zohledněn pomocí několika vztahů. Mezi příklady lze uvést koeficient (k) pro výpočet smykové únosnosti nosníku/desky dle ČSN EN 1992 [9] a obdobný koeficient (λs) dle ACI 318 – 19 [1]. V souvislosti s předloženým článkem je rovněž nezbytné zmínit vztah pro stanovení průměrné pevnosti v tahu za ohybu dle ČSN EN 1992 [9] (fctm,fl):

kde d, resp. h odpovídá účinné výšce, resp. celkové výšce nosníku nebo desky. Obdobně je možné nalézt vztahy zohledňující size effect např. i při výpočtu tahové a ohybové pevnosti dřeva dle ČSN EN 1995 [10].

Vliv orientace tělesa

Při výrobě prvků z cementových kompozitů s ocelovými vlákny pomocí běžné technologie monolitického odlití do formy/bednění může vlivem gravitace docházet k segregaci (klesnutí) drátků ke spodnímu povrchu. Tento efekt je umocněn, pokud je navíc při výrobě použito zhutnění vibrováním. Při monolitické betonáži mají vlákna zároveň tendenci orientovat se podél formy (tzv. stěnový efekt). Tyto jevy byly popsány a experimentálně ověřeny např. v [12], [13]. Společným důsledkem je výrazně nižší ohybová pevnost, pokud je těleso zatěžováno v obrácené poloze oproti poloze při výrobě.

Technologie 3D tisku mnoho z výše uvedených jevů eliminuje nebo výrazně redukuje. Jednotlivé vrstvy obsahují stejné množství drátků, zhutňování se neprovádí a vlákna nejsou usměrňována stěnami formy, ale jejich směr je řízen přímo extruzí hmoty při tisku, jak již bylo prokázáno autory [15].

Jediným jevem, který je de facto shodný s monolitickou výrobou a který by mohl snižovat pevnost při opačné orientaci tělesa, je nižší kvalita (drsnost) horního povrchu vyrobeného prvku. Předpokladem autorů před zahájením výzkumu tedy bylo, že v méně kvalitním horním povrchu může dříve vzniknout trhlina a tím může být snížena výsledná pevnost.

Experimentální program

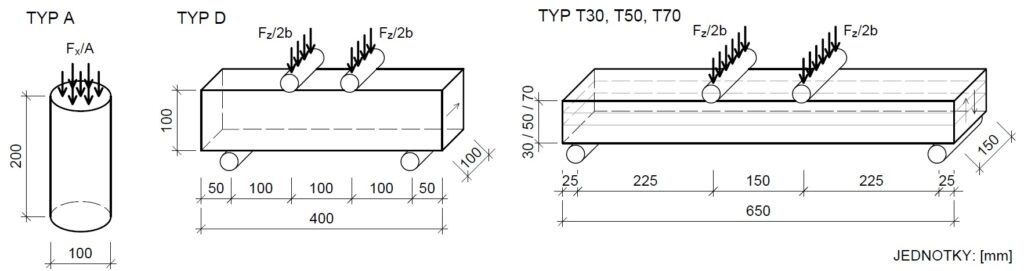

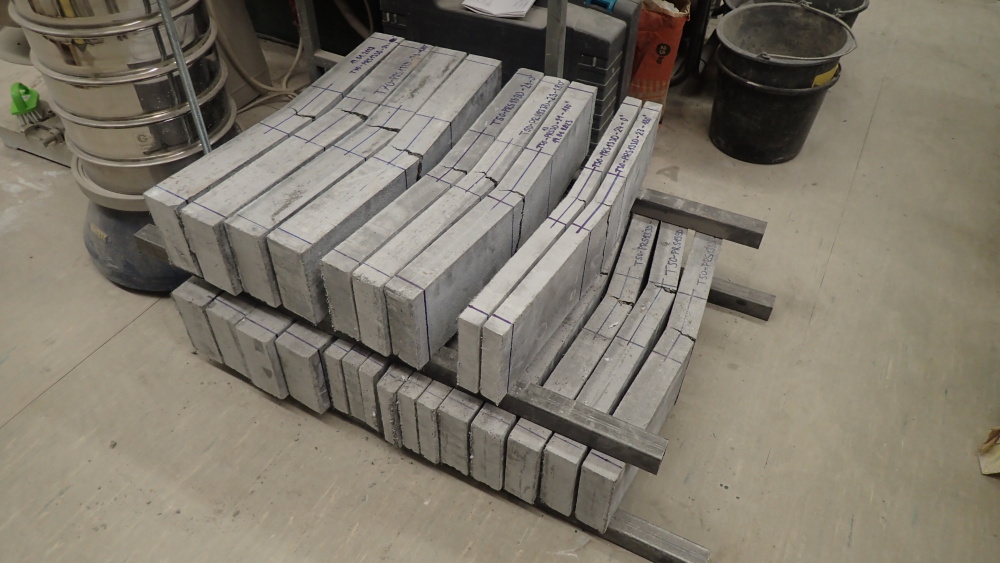

Experimentální program byl sestaven tak, aby bylo možné s dostatečnou přesností a jistotou vyhodnotit výše popsané jevy. Původním záměrem bylo vyrobit desková tělesa, u kterých by bylo dosaženo rovinné napjatosti za ohybu, tedy prvky, jejichž dva půdorysné rozměry by byly vždy minimálně 5× (lépe 10×) větší než tloušťka. Z praktických důvodů bylo nakonec upuštěno od cíle dosažení rovinné napjatosti a finální geometrie prvků tak spíše odpovídá tzv. tenkým trámcům, tedy prutovým ohýbaným prvkům, u nichž převládá délka a výška (tloušťka) průřezu zároveň odpovídá přibližně 1/5 až 1/2 jeho šířky. Tělesa označená jako T30, T50 a T70 byla vyrobena v následujících rozměrech (tloušťka × šířka × délka) a počtech:

- T30 – 30 × 150 × 650 mm (8 + 8 ks),

- T50 – 50 × 150 × 650 mm (8 + 8 ks),

- T70 – 70 × 150 × 650 mm (8 + 8 ks).

Pro porovnání výsledků s předchozí fází výzkumu a pro ověření kvality vyrobeného UHPC byla navíc naplánována výroba několika referenčních těles se základní geometrií odpovídající normovým požadavkům:

- A – válec 100 × 200 mm (6 ks),

- D – trámec 100 × 100 × 400 mm (6 ks).

Geometrie všech zmíněných těles je znázorněna na obrázku níže.

Pro výrobu UHPC byla použita suchá směs od výrobce PREMIX servis, spol. s r.o., s optimalizovanou recepturou pro tisk. Rozptýlená výztuž byla přidána ve formě vysokopevnostních ocelových mikrovláken délky 13 mm (Ø 0,2 mm) v dávce 120 kg/m3. Pro zajištění shodné geometrie všech těles probíhal tisk „na ležato“ do forem z překližky a směr extruze, resp. pohyb tiskové hlavy, byl ve všech vrstvách výhradně v podélném směru těles. Tělesa byla následně přibližně 2 až 3 dny ošetřována ponořením do vody a poté již skladována na vzduchu bez ošetřování tak, aby podmínky co nejvíce odpovídaly skutečné sériové výrobě.

Každá skupina trámců byla vyráběna ze čtyř záměsí, aby byly eliminovány náhodné výrobní vlivy – první dvě záměsi byly připraveny v říjnu 2022, další dvě až v lednu 2023. Je potřeba poznamenat, že referenční tělesa, spolu s polovinou tenkých trámců, byla vyrobena až v rámci lednových záměsí a v tomto období již byla překročena expirační doba suché směsi, což mírně ovlivnilo dosažené výsledky, viz další kapitoly.

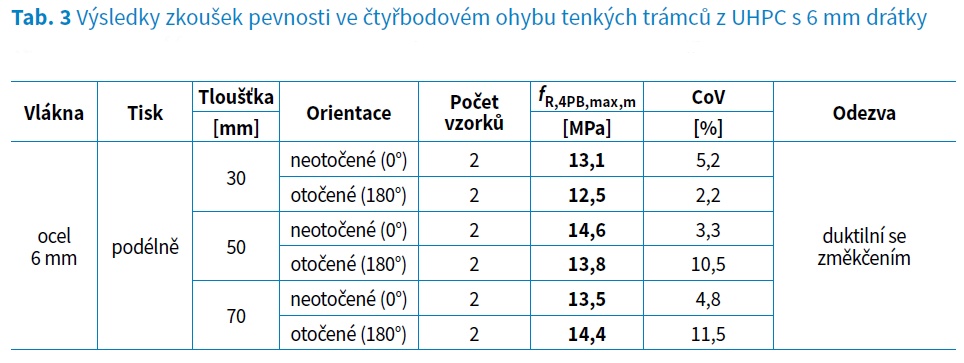

Nad rámec výše uvedených těles bylo vyrobeno ještě několik dalších trámců T30 až T70 s ocelovými mikrovlákny délky pouze 6 mm. Výsledky zkoušek na těchto tělesech jsou v dalších částech prezentovány pouze okrajově, spíše za účelem porovnání s drátky délky 13 mm.

Laboratorní zkoušky

Zkoušky probíhaly v průběhu listopadu a prosince 2022 a dále v průběhu února 2023, přičemž průměrné stáří každé skupiny těles se pohybovalo v rozmezí 28 až 38 dní.

Průběh zkoušek

Na referenčních válcích 100 × 200 mm byla provedena zkouška v tlaku v souladu s ČSN EN 12390 – 3 [6] (zatěžování předepsaným napětím 0,6 MPa/s). Měření statického ani dynamického modulu pružnosti na válcích provedeno nebylo.

Všechna ostatní tělesa byla zkoušena ve čtyřbodovém ohybu, přičemž u trámců 100 × 100 × 400 mm byly osové vzdálenosti mezi podporami a zatěžovacími válci 100 + 100 + 100 mm, zatímco u tenkých trámců (30 – 70) × 150 × 650 mm byly vzdálenosti 225 + 150 + 225 mm, tzn. celkové rozpětí 600 mm (viz také obr. 1). Trámce čtvercového průřezu byly do lisu umístěny v poloze otočené o 90° oproti směru výroby, tj. v souladu s principy norem ČSN EN 12390 – 5 [7] a ČSN P 73 2452 [11]. Naopak tenké trámce byly, s ohledem na hlavní záměr výzkumu, vkládány do lisu v polovině případů v neotočené poloze (0°) a v druhé polovině případů v plně otočené poloze (180°) vzhledem k poloze při výrobě.

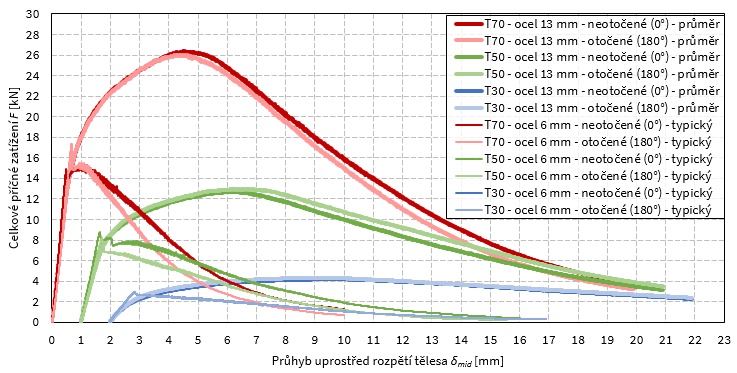

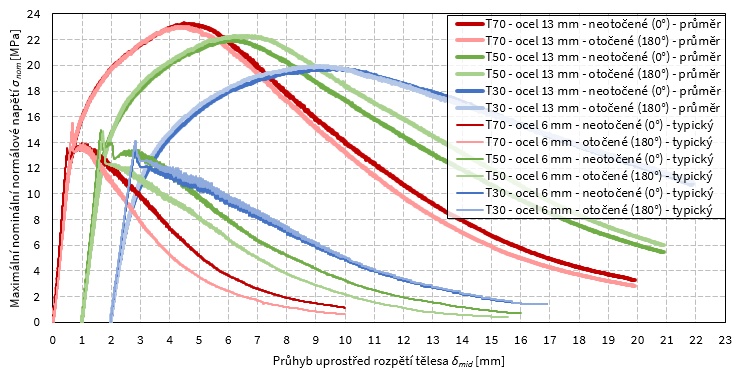

Ohybové zkoušky byly řízeny předepsaným posunem (průhybem), jehož rychlost byla vhodně zvolena na základě ohybové tuhosti jednotlivých těles (tenká tělesa s nízkou tuhostí byla zatěžována rychleji). Rychlost posunu byla vždy zdvojnásobena za vrcholem pracovního diagramu. V průběhu zkoušek byla zaznamenávána síla na lisu a průhyb uprostřed rozpětí, který byl omezen rozsahem snímačů přibližně do 20 mm. Mimo záznam bylo ovšem několik trámců tloušťky 30 mm zkoušeno i po odpojení snímačů a podařilo se dosáhnout průhybu většího, než byla tloušťka samotného tělesa, aniž by došlo k jeho zlomení. Tím byla demonstrována mimořádná duktilita tenkých prvků z UHPC vyztužených ocelovými mikrovlákny.

Výsledky zkoušek

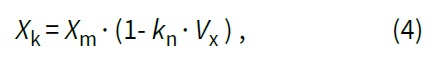

Ze zkoušek jednotlivých skupin těles byly stanoveny průměrné hodnoty mechanických vlastností a zároveň s využitím statistického vyhodnocení a s uplatněním přílohy D k normě ČSN EN 1990 [8] byly stanoveny i charakteristické hodnoty vlastností podle vztahu:

kde Xk je charakteristická hodnota vlastnosti, Xm průměrná hodnota vlastnosti, kn koeficient kvantilu charakteristické hodnoty závislý na počtu zkoušek ve skupině těles a Vx variační koeficient (někdy též značen CoV).

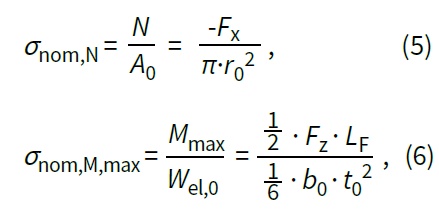

Při vyhodnocování mechanických vlastností bylo vždy uvažováno nominální (inženýrské) napětí, tzn. napětí vztažené k počátečnímu nedeformovanému a nepoškozenému stavu tělesa:

kde σnom,N je normálové napětí od normálové síly, σnom,M,max je maximální normálové napětí od ohybového momentu, Fx osová síla, Fz celková příčná síla, LF osová vzdálenost mezi podporou a nejbližším zatěžovacím válcem, r0 počáteční poloměr válce, b0 počáteční šířka trámce a t0 počáteční tloušťka (výška) trámce.

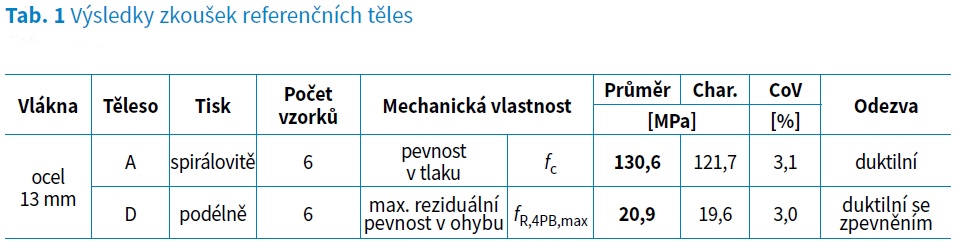

Nejprve byla vyhodnocena referenční tělesa, u kterých se variační koeficient pohyboval okolo 3 %. Na válcích bylo dosaženo průměrné pevnosti v tlaku 131 MPa a charakteristické pevnosti 122 MPa, což odpovídá třídě UHPC C120 dle TP ČBS 07 [14]. Na trámcích čtvercového průřezu bylo dosaženo průměrné maximální reziduální pevnosti v ohybu 20,9 MPa a charakteristické hodnoty 19,6 MPa.

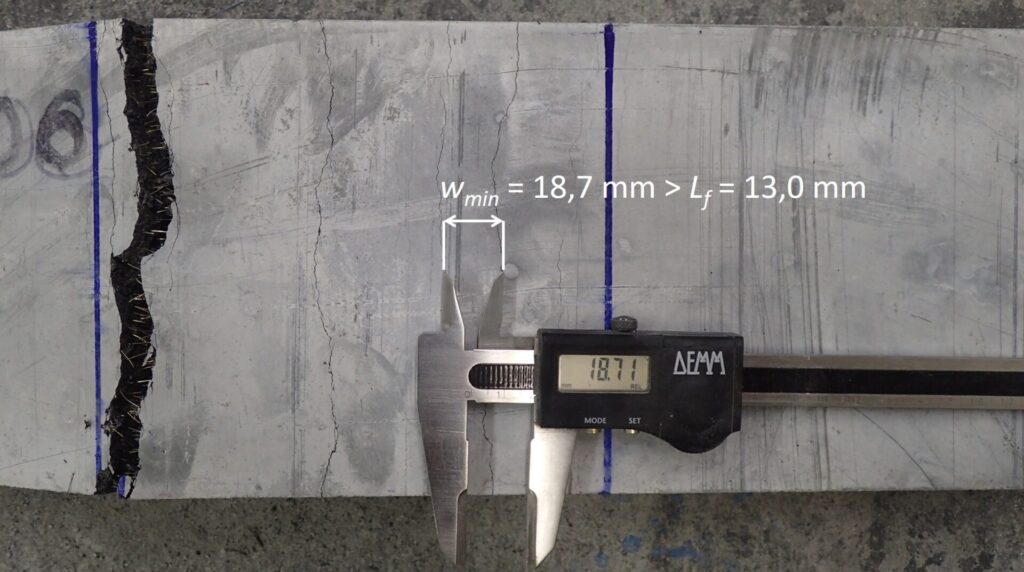

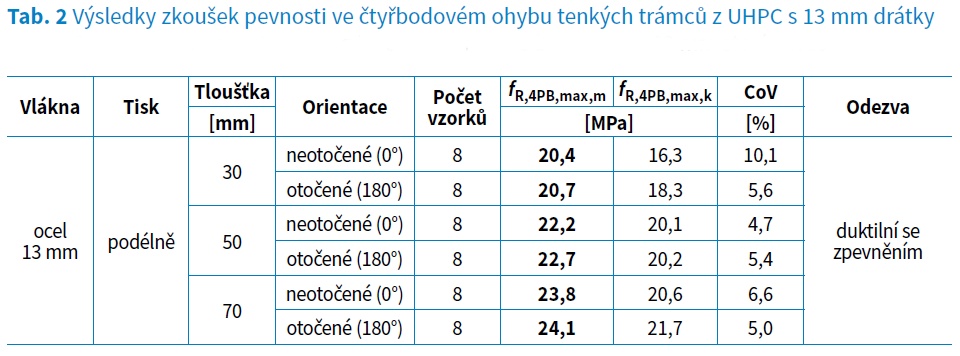

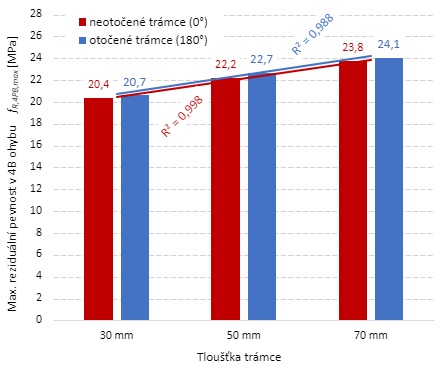

V případě tenkých trámců s drátky délky 13 mm byl variační koeficient vyšší, v rozmezí 5 až 10 %, což bylo způsobeno výrobou části trámců ze směsi po expiraci (viz předchozí kapitola). Při zkouškách bylo nicméně dosaženo průměrné maximální reziduální pevnosti v ohybu 20 až 24 MPa. Stav trámců po zkouškách je patrný z obázku níže, rozmístění makrotrhlin v tažené oblasti trámce je vidět na následujícím obrázku.

Tenké trámce s drátky délky 6 mm vykazovaly variační koeficient v rozmezí 2 až 12 % a výrazně nižší průměrnou maximální reziduální pevnost v ohybu – přibližně 12 až 15 MPa.

Veškeré výsledky jsou přehledně shrnuty v níže uvedených tabulkách a grafech.

Vyhodnocení výsledků a diskuze

Z výsledků zkoušek referenčních těles (válců a trámců čtvercového průřezu) prezentovaných v tabulkách je patrné, že překročení expirační doby suché směsi mělo zanedbatelný vliv na pevnost v tlaku – bylo dosaženo třídy C120, což velmi dobře odpovídá výsledkům z první fáze výzkumu [15], při které bylo dosaženo třídy C120 až C130. Naopak vliv na maximální reziduální pevnost v ohybu byl vyšší, kdy referenční tělesa v této fázi výzkumu vykázala průměrnou hodnotu přibližně 21 MPa, tedy přibližně o 15 % nižší než v první fázi výzkumu [15], kdy bylo dosaženo hodnoty přibližně 25 MPa.

Hlavním cílem zkoušek nicméně bylo vyhodnocení vlivu velikosti (tloušťky) a orientace těles na ohybovou pevnost. Z výsledků dosažených při zkouškách na celkem 60 tělesech o třech různých tloušťkách a dvou délkách drátků, které jsou přehledně prezentovány formou tabulek, fotografií a především grafů, lze učinit následující závěry:

- orientace těles vyrobených pomocí 3D tisku má zcela zanedbatelný vliv na pevnost a celkovou odezvu v ohybu (maximální rozdíl 2,3 %), mírně vyšší hodnoty paradoxně vykazovala tělesa otočená o 180°,

- vliv tloušťky těles na ohybovou pevnost byl prokazatelně pozorován, ale v přesně opačném smyslu než předpokládá teorie size effectu – trámce větší tloušťky vykázaly vždy vyšší pevnost (při tloušťce 70 mm byl nárůst pevnosti přibližně 17 % oproti tloušťce 30 mm),

- zjištěná závislost mezi tloušťkou a pevností je téměř dokonale přímo úměrná (lineární), viz regresní křivky na obrázku ohledně porovnání průměrné max. reziduální pevnosti v ohybu (tato závislost ale samozřejmě nemůže být neomezená a platí v rozsahu zkoumaných tlouštěk 30, 50 a 70 mm),

- odezva tenkých trámců z UHPC s drátky délky 13 mm byla vždy duktilní s výrazným zpevněním (ve fázi od vzniku první trhliny přes vznik dalších trhlin až po výběr dominantní trhliny narostlo nominální normálové napětí často až o 100 %),

- mimořádné duktility dosahovaly především nejtenčí zkoumané trámce tloušťky 30 mm, kdy bylo možné těleso prohnout až o hodnotu vlastní tloušťky, aniž by došlo k jeho zlomení,

- vzdálenost mezi makrotrhlinami v tažené oblasti nikdy nebyla nižší než délka drátků,

- informativně zkoumané trámce s drátky délky pouze 6 mm ihned po vzniku první trhliny přecházely do fáze duktilního změkčení, maximální ohybová pevnost odpovídala jen asi 60 % pevnosti trámců s drátky délky 13 mm.

Uvedené závěry přináší několik zajímavých poznatků k problematice 3D tisku UHPC. Dle očekávání nedochází při výrobě k žádné segregaci drátků, a navíc kvalita rubového a lícového povrchu (ač vizuálně odlišitelná) nemá žádný měřitelný vliv na výslednou pevnost. Ohýbané prvky tedy mohou být zatěžovány v libovolném směru, nezávisle na poloze při výrobě, bez negativního dopadu na výslednou únosnost.

Velmi zajímavým a do jisté míry překvapivým výsledkem je přímá úměra mezi tloušťkou tělesa a naměřenou ohybovou pevností, tedy v principu opačný size effect. Je zřejmé, že lineární závislost nemůže být platná neomezeně a při určité tloušťce tělesa bude pravděpodobně dosaženo maxima nebo bude hodnota pevnosti konvergovat k limitní hodnotě. Této situace se nicméně v měřeném rozsahu tlouštěk nepodařilo dosáhnout. Atypické chování, kdy tělesa větších tlouštěk vykazují vyšší pevnost, může být do jisté míry způsobeno vrstevnatostí těles vlivem technologie výroby. Jak je vidět mj. z diagramů na závislosti napětí na průhybu tenkých trámců ve čtyřbodovém ohybu trámce tloušťky 30 mm, vykazují nelineární odezvu již v brzké fázi zatěžování, přibližně při dosažení napětí 8 MPa, zatímco trámce tloušťky 70 mm přibližně od 12 až 14 MPa. Jelikož je v případě malé tloušťky vystavena výraznému tahu pouze jediná krajní vrstva, je v ní velmi brzy nalezeno nejslabší místo, kde vznikne první trhlina. Naopak při větší tloušťce je výrazně taženo hned několik krajních vrstev a pravděpodobnost, že se ve všech těchto vrstvách bude nacházet nejslabší místo na stejném místě, je nižší, což může bránit vzniku makrotrhliny.

Jako poslední důležitý závěr lze uvést, že UHPC s velmi krátkými drátky (6 mm) nevykazuje zpevnění po vzniku první trhliny, neboť kvůli velmi malé kotevní délce nedokáží drátky přemostit prvotní trhlinu, a proto maximální reziduální ohybová pevnost přímo odpovídá pružné ohybové pevnosti. V porovnání s vyztužením delšími drátky (13 mm), které vykazuje výrazné zpevnění, je tak UHPC s velmi krátkými drátky nevhodné pro použití na nosné konstrukce.

Porovnání s monolitickým UHPC

V roce 2019 prezentoval Holý a kol. [12] výsledky laboratorních zkoušek, které byly svým uspořádáním i zaměřením velmi podobné zkouškám prezentovaným v tomto článku. Jediným výrazným rozdílem byla skutečnost, že tělesa byla vyráběna běžným odlitím do formy. Z výsledků tohoto výzkumu vyplynulo, že u monolitického UHPC je pozorován klasický size effect, kdy s rostoucí tloušťkou prvku klesá ohybová pevnost, a navíc tělesa zkoušená v obrácené poloze oproti poloze při výrobě vykazují o 15 až 20 % nižší ohybovou pevnost. Výsledky 3D tištěného UHPC jsou tedy v přímém kontrastu s monolitickým UHPC.

Budoucí vývoj

V době vydání tohoto článku autoři již dokončují další fázi výzkumu zaměřenou na soudržnost mezi UHPC tištěným bez formy a dodatečnou monolitickou dobetonávkou z běžného betonu. Výsledky budou pravděpodobně publikovány v některém z následujících vydání časopisu Beton.

Závěr

V článku popisujícím navazující výzkum 3D tisku UHPC s ocelovými mikrovlákny byly představeny výsledky laboratorních zkoušek zaměřených na odezvu tenkých ohýbaných prvků. Zkoumaná tělesa v rozmezí tlouštěk 30 až 70 mm vykázala mírný nárůst maximální reziduální ohybové pevnosti s rostoucí tloušťkou (tedy jev opačný k tradičnímu size effectu), a to od 20 MPa při minimální tloušťce po 24 MPa při maximální tloušťce. Zároveň bylo zkouškami zjištěno, že směr ohybu vzhledem ke směru výroby nemá žádný vliv na změřené mechanické vlastnosti.

Doplňkovými zkouškami bylo prokázáno, že pomocí vyztužení delšími ocelovými drátky lze dosáhnout mnohem lepší ohybové odezvy i pevnosti oproti vyztužení drátky velmi krátkými, které nedokáží vlivem malé kotevní délky zajistit zpevnění materiálu.

Literatura

[1] ACI 318 – 19. Building Code Requirements for Structural Concrete. ACI Committee 318, 2019.

[2] BAŽANT, Z. P. Size effect on structural strength: a review. Archive of Applied Mechanics. 1999, Vol. 69, s. 703 – 725.

[3] BAŽANT, Z. P. Size effect. International Journal of Solids and Structures. 2000, Vol. 37, s. 69 – 80.

[4] BAŽANT, Z. P., PLANAS, J. Fracture and Size Effect in Concrete and Other Quasibrittle Materials.

1st ed. New York: CRC Press, 1998. ISBN 0 – 8493 – 8284‑X.

[5] BAŽANT, Z. P., QIANG, Y. Universal Size Effect Law and Effect of Crack Depth on Quasi-Brittle Structure Strength. Journal of Engineering Mechanics. 2009, 135(2), s. 78 – 84.

[6] ČSN EN 12390 – 3. Zkoušení ztvrdlého betonu – Část 3: Pevnost v tlaku zkušebních těles. ICS 91.100.30. Praha: ÚNMZ, 2020.

[7] ČSN EN 12390 – 5. Zkoušení ztvrdlého betonu – Část 5: Pevnost v tahu ohybem zkušebních těles. ICS 91.100.30. Praha: ÚNMZ, 2020.

[8] ČSN EN 1990. Eurokód: Zásady navrhování konstrukcí. ed. 2. ICS 91.010.30. Praha: ÚNMZ, 2015.

[9] ČSN EN 1992 – 1‑1. Eurokód 2: Navrhování betonových konstrukcí – Část 1 – 1: Obecná pravidla a pravidla pro pozemní stavby. ed. 2. ICS 91.010.30; 91.080.40. Praha: ÚNMZ, 2019.

[10] ČSN EN 1995 – 1‑1. Eurokód 5: Navrhování dřevěných konstrukcí – Část 1 – 1: Obecná pravidla – Společná pravidla a pravidla pro pozemní stavby. ICS 91.010.30; 91.080.20. Praha: ČNI, 2006.

[11] ČSN P 73 2452. Vláknobeton – Zkoušení ztvrdlého vláknobetonu. ICS 91.100.30. Praha: ÚNMZ, 2015.

[12] HOLÝ, M., TEJ, P., KOLÍSKO, J., VRÁBLÍK, L. Experimentální stanovení ohybové pevnosti desek z UHPC. Beton TKS. 2019, roč. 19, č. 5, s. 48 – 51.

[13] RYDVAL, M. Technologie a vlastnosti UHPC. Praha, 2019. 142 s. Disertační práce. ČVUT v Praze, Kloknerův ústav, Oddělení experimentálních a měřicích metod. Školitel doc. Ing. Jiří Kolísko, Ph.D.

[14] Technická pravidla ČBS 07. Ultra vysokohodnotný beton (UHPC). Praha: ČBS ČSSI, 2022.

[15] VESECKÝ, J., KUBÁT, J., KUŽNÍK, M., DÍAZ, F., NIKITIN, D., VRÁBLÍK, L. PŘÍBRAMSKÝ, V. 3D tisk UHPC s ocelovými mikrovlákny: ověření mechanických vlastností zkušebních těles. Beton TKS. 2022, roč. 22, č. 3, s. 78 – 85.

[16] WEIBULL, W. A statistical distribution function of wide applicability. Journal of Applied Mechanics. 1951, Vol. 18, s. 293 – 297.

Autoři článku děkují doc. Josefu Fládrovi, Ing. Romanu Chylíkovi a Ing. Tomáši Trtíkovi z Katedry betonových a zděných konstrukcí FSv ČVUT za pomoc při provádění laboratorních zkoušek.

Výzkum byl spolufinancován z projektu Ministerstva průmyslu a obchodu CZ.01.1.02/0.0/0.0/20_321/0025126 Výzkum a vývoj využití UHPC pro hlavní konstrukční prvky inženýrských konstrukcí dopravních staveb.